Generally speaking, the hydraulic motor has three oil ports, one is the oil inlet, one is the oil return port, and one is the oil drain port. The oil inlet and return ports are the pipes for hydraulic transmission oil to enter and exit the hydraulic motor, and must be connected. Does the drain pipe need to be connected?

Generally, the pipe thread of the oil drain port of the hydraulic motor is much smaller than that of the oil inlet and outlet, mainly to drain the hydraulic transmission oil leaked from the hydraulic motor out of the motor housing. After the high-pressure oil enters the hydraulic motor, the sealing of the stator, rotor and other parts based on the hydraulic motor is mainly through the lubrication film, so the high-pressure oil will inevitably penetrate into the motor housing, so that the leaked oil will accumulate in the motor housing of the hydraulic motor, and will accumulate more if it is not discharged early, The leakage working pressure inside the motor housing will become larger and larger, which will not only damage the seal, but also burst the motor housing! Then I will go from Cycloid hydraulic motor And plunger hydraulic motor.

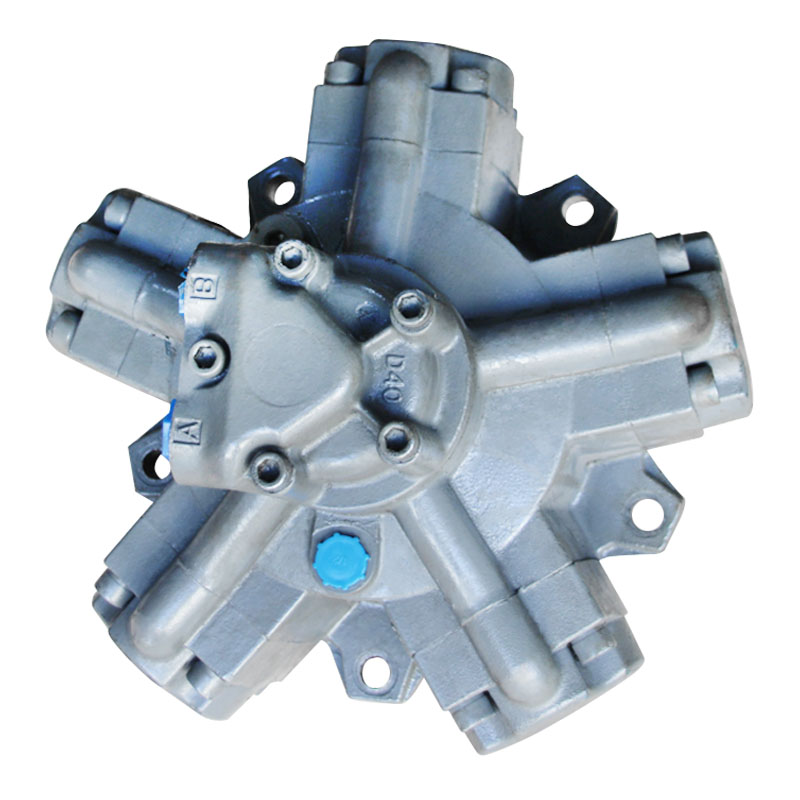

Cycloidal motor with large radial force

orbit motor After the motor housing is filled with the leaked oil, it must be drained out of the motor housing unnecessarily. If the oil drain pipe is not connected, for the hydraulic motor with built-in check valve, the leaked oil will flow into the return pipe through the built-in check valve and into the hydraulic oil tank through the return pipe. If the hydraulic motor does not have a built-in check valve, the oil leakage in the hydraulic motor will accumulate more and more, which will cause the torque of the hydraulic motor to drop, and the seal ring at the shaft end to be damaged. Therefore, the cycloidal hydraulic motor usually needs to be connected with a drain pipe.

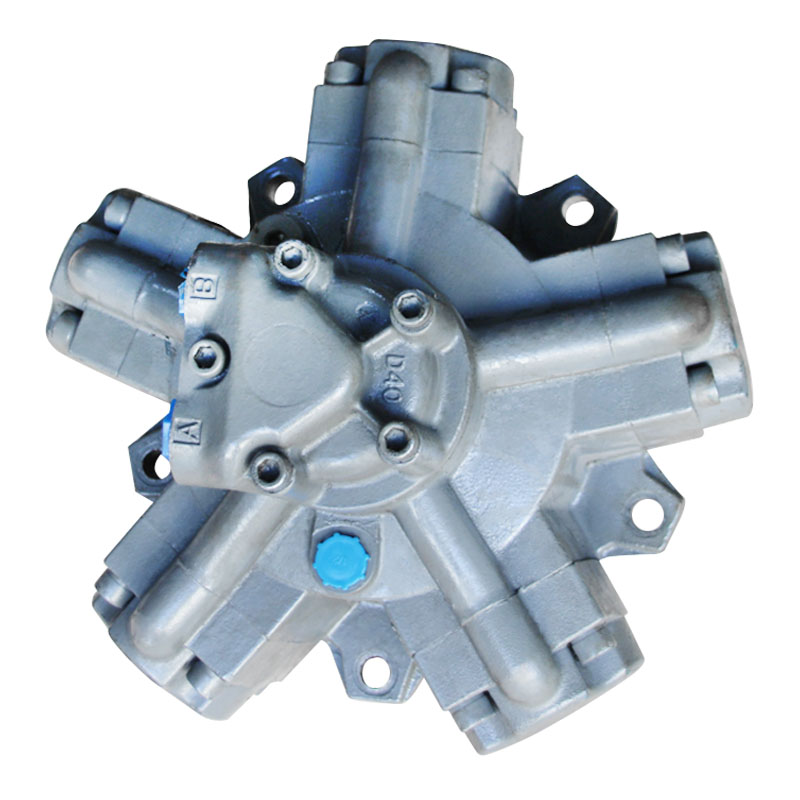

Hydraulic cycloidal slewing motor

When the high-pressure oil enters the plunger cavity of the hydraulic motor, the hydraulic transmission oil will also leak into the motor housing with the help of motor rotor, oil distribution plate and other parts. This is the internal drain oil of the hydraulic motor. The internal drain oil will lubricate the rolling bearings and other friction pairs, but too much hydraulic transmission oil will accumulate in the motor housing, which will increase the working pressure in the motor housing, which can directly damage the shaft end seal ring, or even burst the motor housing. Therefore, the oil drain port of the plunger hydraulic motor must be connected with the external oil drain pipe. Since there is no built-in check valve component, the oil leaked inside must flow to the hydraulic oil tank through the oil drain port.

Generally speaking, hydraulic motors in specific cases need to be connected with drain pipes, and few specific cases do not need to be connected with drain pipes.

![]()