Hydraulic motor It is an important actuator in the hydraulic system, which can convert the hydraulic energy in the hydraulic system into mechanical energy to achieve various mechanical actions. According to its working principle and structural characteristics, hydraulic motors can be divided into many types, among which Cycloid hydraulic motor and Plunger type hydraulic motor They are two commonly used types. This article will focus on the differences between the two hydraulic motors.

1、 Characteristics of cycloidal hydraulic motor

Cycloidal hydraulic motor is a kind of hydraulic motor that realizes torque output by rotating the internal cycloidal gear. Its main characteristics are as follows:

1. Small pressure angle: The pressure angle of the cycloidal hydraulic motor is generally about 15 degrees. Under the conditions of high torque and low speed, the cycloidal hydraulic motor has great advantages in output torque.

2. Stable output torque: The cycloidal gear of the cycloidal hydraulic motor has high design and manufacturing accuracy, which makes the output torque of the cycloidal hydraulic motor stable and reliable.

3. Good continuity of torque output: When the cycloidal hydraulic motor outputs torque, the shape of the gear pair determines the continuity of the output torque, making its torque output more continuous.

4. Self contained stability: Since there are many mechanical transmission elements inside the cycloidal hydraulic motor, it has its own inertia and stability, so that it can also maintain good stability under variable load conditions.

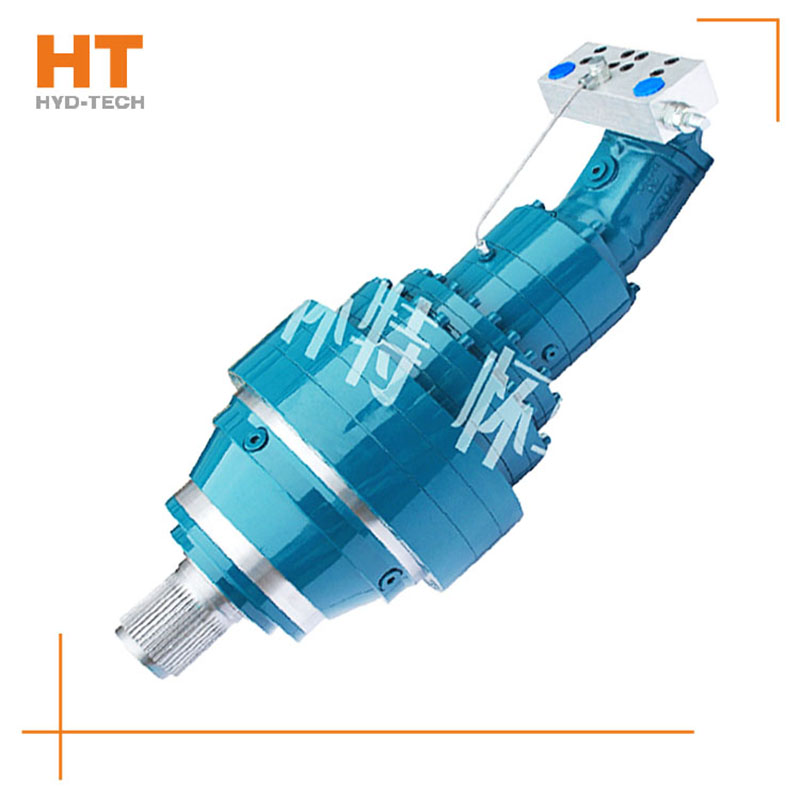

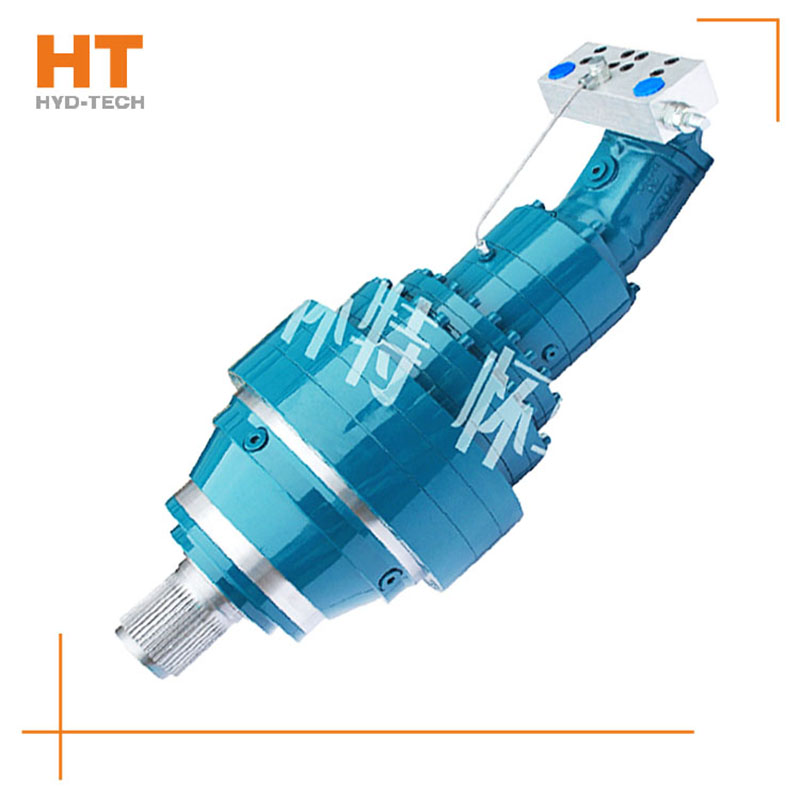

2、 Characteristics of plunger type hydraulic motor

The plunger type hydraulic motor is a hydraulic motor that realizes torque output by reciprocating motion of the plunger in the pump body. Its main characteristics are as follows:

1. High output power: because the plunger type hydraulic motor uses multiple plungers corresponding to multiple inlets and outlets, the torque output capacity of the plunger type hydraulic motor is strong under the condition of the same displacement.

2. Wide speed range: the plunger type hydraulic motor can produce a larger torque output at a lower speed, while maintaining a more stable torque output at a high speed.

3. Wide range of speed change: The plunger type hydraulic motor has good speed change performance, and its output torque can gradually decrease with the increase of rotation speed. In the system, the torque can be adjusted by adjusting the pressure or flow.

4. Compact structure: The plunger type hydraulic motor is compact in structure and easy to assemble, so it is widely used in construction machinery and other places.

3、 Distinctive comparison

1. Different structures

The torque output mechanism of the cycloidal hydraulic motor is a cycloidal gear, and the way of transmitting torque is realized by the teeth on different gear rims. The plunger type hydraulic motor realizes torque output by the reciprocating motion of the plunger in the pump body.

2. Different ways of power take-off

The cycloidal hydraulic motor has relatively soft power output mode, stable output torque and certain continuity, which is very suitable for high torque and low speed working environment; The power output mode of plunger type hydraulic motor is relatively rigid, with large power output, wide speed range, wide speed range and suitable working environment.

3. Different work efficiency

Relatively speaking, the conversion efficiency of cycloidal hydraulic motor is lower than Piston Motors 。 However, the cycloidal hydraulic motor requires less mechanical parts, simple structure and low maintenance cost.

4. Different application fields

Because the cycloidal hydraulic motor is suitable for high torque and low speed environment, it is suitable for various lifting equipment, stage machinery and other fields; The plunger type hydraulic motor has the advantages of large power, wide speed range and wide speed range, so it is suitable for various mobile equipment, construction machinery and other fields.

In a word, there are differences between the cycloidal hydraulic motor and the plunger hydraulic motor in structure, power output mode, work efficiency and application fields. Users should choose according to different requirements. In practical applications, hydraulic motors need to be selected according to specific conditions to achieve better efficiency.

![]()