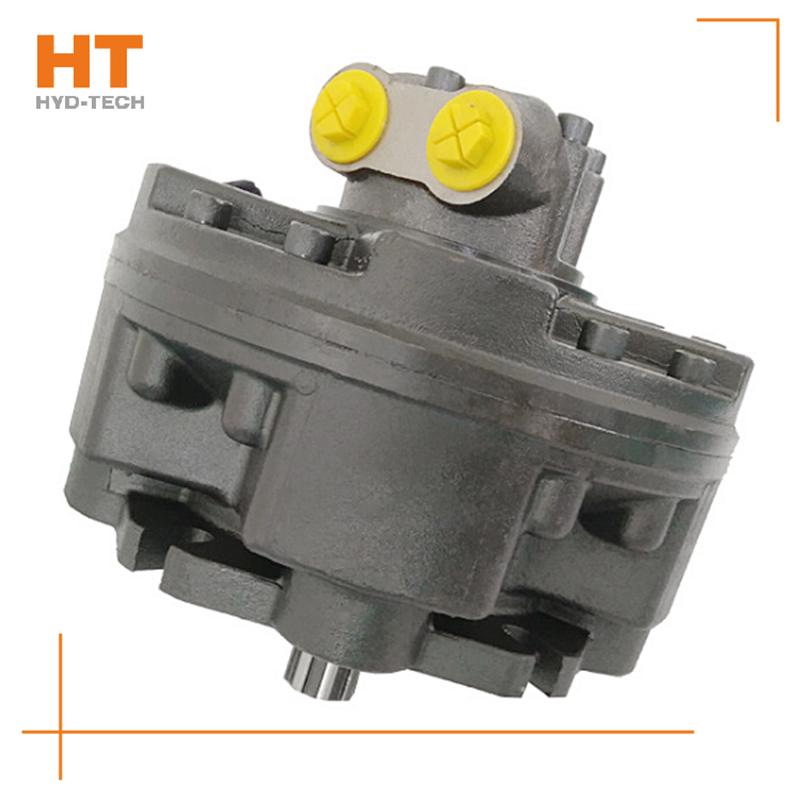

The port plate is one of the main components of the plunger motor, which is used to isolate and distribute the oil at the inlet and outlet, and bear the axial load from the high-speed rotating cylinder. Its design directly affects the efficiency and life of the motor. The design of the port plate is mainly to determine the size of the inner and outer sealing belts, the oil inlet and outlet windows, and the size of each part of the auxiliary support surface. TJVM3 motor adopts spherical current distribution structure.

Allocates the size of the window.

The diameter of the flow window distribution circle is generally equal to or less than the diameter of the plunger distribution circle, Cycloidal hydraulic motor brake It is connected with the oil hole at the end of the cylinder block plunger cavity to reduce the relative sliding speed between the valve plate and the cylinder block.

Size of the sealing tape.

In view of the large flow and high working pressure of the motor, the surface of the valve plate should be equipped with an external sealing belt (because of the large radius, Hydraulic cycloidal slewing motor The centrifugal force causes relatively large leakage), but because the ball valve structure has good sealing performance, the inner sealing belt should not be set.

Material selection of orifice plate.

The material of the port plate shall be the material corresponding to the cylinder block, OMT cycloidal hydraulic motor Common materials shall be matched. The occlusal ability of ZQSn10-1 and Cr12MoV. After the port plate is quenched (or nitrided steel flakes), in order to stabilize the metallographic structure, cold treatment and aging treatment are usually required. Sometimes, in order to improve its running in and corrosion resistance, the bronze cylinder surface should be coated with lead or lead indium.

The process requirements of orifice plate are as follows:

1) Ensure spherical surface and spherical diameter, runout and surface roughness;

2) The surface roughness of the port plate should be about 0.4~0.1um, and the tolerance of surface flatness should be about 0.005mm, and it can only be concave, not convex. In addition, the symmetry of both sides of the valve plate shall also meet the design requirements;

3) The hardness after heat treatment shall meet the design requirements (above 50HRC);

4) After polishing, the parts shall be free of bumps and scratches.

![]()