Hydraulic motor The rotation speed of is determined by the flow rate input to the hydraulic motor. The output torque is related to the displacement of the hydraulic motor and the pressure difference between the oil inlet and outlet of the hydraulic motor.

The rotation speed can be divided into running rotation speed, rated rotation speed, extremely high rotation speed and extremely low stable rotation speed, r/min. Running rotation speed refers to the actual running speed of hydraulic oil pump (or hydraulic motor) during operation. The rated rotation speed refers to the extremely high rotation speed at which the hydraulic oil pump (or hydraulic motor) can continue to operate for a long time under the rated pressure.

That is, when the rotation speed exceeds the rotation speed, the hydraulic oil pump (or hydraulic motor) will not absorb enough oil, resulting in vibration and noise, cavitation damage, and reduced service life. Extreme high rotational speed refers to the extreme high rotational speed limit that cannot be exceeded when the hydraulic oil pump (or hydraulic motor) will not be damaged abnormally. The extremely low steady rotation speed refers to the extremely low rotation speed allowed by the normal operation of the hydraulic motor.

The rotation speed function of the hydraulic oil pump (or hydraulic motor) is disturbed by the flow and the load of rotating parts and mechanical equipment. It is a function of the displacement and pressure. Generally, when the pressure decreases or the displacement decreases, the rotation speed function of the hydraulic oil pump (or hydraulic motor) increases.

Under the same pressure, the rotation speed increases with the decrease of displacement, and will not increase again when reaching the limit value when reaching a certain displacement between the minimum displacement (not necessarily zero displacement) and the full displacement. Under the condition of small displacement and extremely high rotation speed, the additional load of inertia force of the rotating parts of the hydraulic oil pump (or hydraulic motor) is huge, which is likely to damage the hydraulic oil pump (or hydraulic motor) or aggravate the damage caused by the extreme value lubrication at the operating position.

Within the rated rotation speed, the service life and transmission efficiency of the hydraulic oil pump (or hydraulic motor) are far less sensitive to the change of rotation speed than to the change of pressure. Therefore, it is appropriate to use the rated rotation speed as the matching rotation speed from the aspects of improving the power utilization rate of the hydraulic oil pump (or hydraulic motor) and saving costs.

The rotation speed of the hydraulic motor is determined by the flow input to the hydraulic motor. The output torque is related to the displacement of the hydraulic motor and the pressure difference between the oil inlet and outlet of the hydraulic motor.

Flow: the flow not included in the leakage is called the basic theoretical flow, and the leakage flow is fully considered as the actual flow.

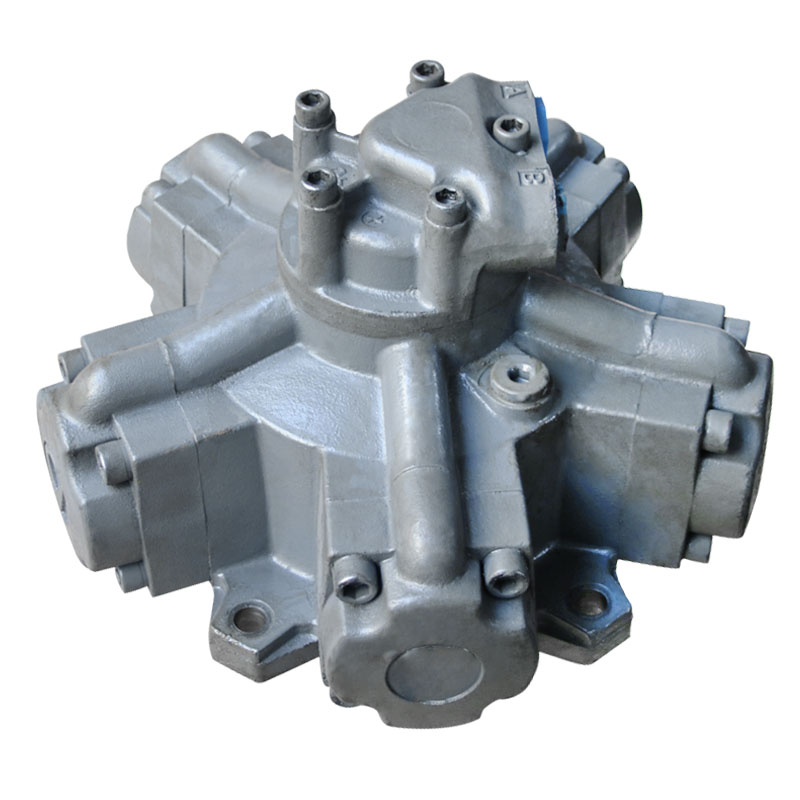

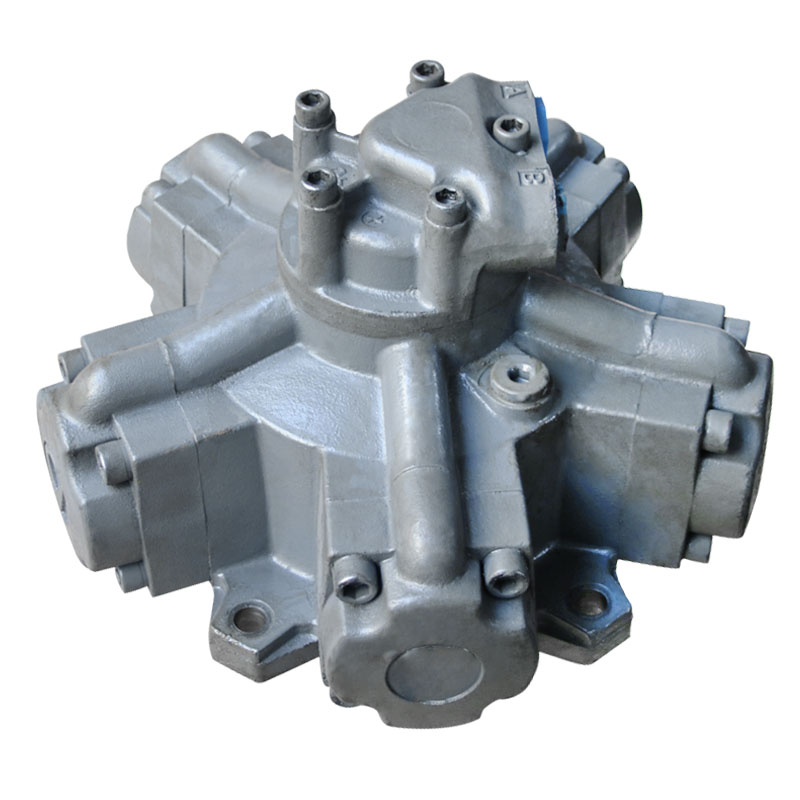

The hydraulic motor is an actuating element of the hydraulic system, which converts the hydraulic pressure energy given by the hydraulic pump into the mechanical kinetic energy (torque and rotational speed) of its output shaft. Liquid is the medium to transmit force and motion.

![]()