The marine radial ball plug produced by Ningbo White Hydraulic Technology Co., Ltd Inner curve hydraulic motor It has the advantages of wide speed range, high efficiency, small size and light weight, and has been widely used.

1 Basic principles

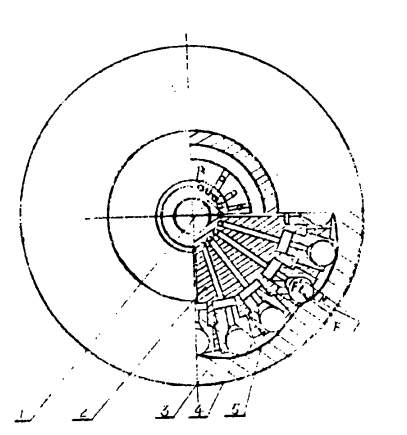

The figure is Inner curve motor schematic diagram. The inner part of the stator is composed of a thousand arc surfaces with identical shapes. Each arc is composed of operation section and oil return section. There are many distributed piston holes in the center direction of the motor rotor body, and the bottom edge of each hole is provided with an oil port, which is interconnected with the corresponding port channel of the port shaft. When the piston enters into the running section of the stator arc surface, the pressure oil enters into the piston through the oil inlet of the distribution shaft to the movable plug hole of the motor rotor body to push the piston, so that the steel ball is pressed on the running section of the stator arc surface. The stator arc surface causes the reaction force N, and the radial component F of the reaction force N is balanced with the hydraulic force, while the tangential component F is transmitted to the motor rotor body. Cause the torque that causes the cylinder head to rotate. When the piston enters the oil return section of the stator arc surface, the oil opening of the piston is interconnected with the oil return port of the port shaft. At this time, the stator arc surface presses the piston back to make the hydraulic oil flow out through the port shaft. The piston repeatedly moves once every time it passes through a curved surface. When the inlet and outlet of the port shaft are reversed, the motor will reverse.

2 Structural characteristics and characteristics

Radial ball plug type is curve Hydraulic motor The commercially purchased standard steel ball is selected as the primary force transmission component of the plunger pair, so the structure is simple, the production is convenient, and the shock resistance is excellent. The piston is gradient cylindrical structure, and the ball socket at the big round end of the piston is bonded with a ball pad made of composite materials. The steel ball is installed in the ball socket. Static pressure support structure is selected between the steel ball and the ball socket. The bottom edge of the ball socket is the hydrostatic oil chamber. The piston hole of motor rotor body is bonded with the cylinder head made of composite materials. The hydrostatic support structure is also used between the piston hole and the big round end of the piston. The pressure oil enters the hydrostatic support through the damping passage on the damping plug. The mechanical capacity of the hydraulic motor can reach more than 95%. The round end of the piston is the effective acting end. The round end is equipped with a plastic piston containing copper powder. The round end of the piston and the cylinder hole have good sealing characteristics and long service life. The arc surface of the stator guide rail is finely machined into an arc shaped groove that is very close to the steel ball. The steel ball slides along the channel, ensuring a very large touch range at the contact position between the steel ball and the channel, and effectively reducing the contact pressure. The structural feature makes the hydraulic motor manufactured by machining. The additional contact pressure value caused by assembly deviation, overall assembly, stress deformation and other reasons is small, so the operation is reliable.

4 Application

Radial ball plug type internal curve hydraulic motor has been widely used. 2QJM-E25 motor has been used as 589kN hydraulic stern windlass for large and medium-sized landing ships. 2QJM-E12.5 and 2QJM-E6.3 motors are also used as 294kN and 157kN hydraulic stern windlass respectively on medium and mini landing ships. The 2QJM-E1.6 motor is installed on the 49kN hydraulic stern windlass, and all of them have been used by naval related enterprises. Among them, 2QJM-E25 and 2QJM-E6.3 motors have been type tested and evaluated by the headquarters of the shipping company. The motor is also used for other special equipment of the ship. For example, the 2QJM-E6.3 shell rotor motor was successfully assembled on the 918 mine laying ship transportation and mine laying system.

![]()

![]()