The basis for distinguishing a four column hydraulic pump station is not only the rationality of the design scheme of the automatic control system, the performance of the system components, and the quality of the production, processing and manufacturing process, but also the pollution safety prevention and treatment of the pump station, Cycloidal hydraulic motor of snowplow The pollution of the pump station will immediately hurt Hydraulic transmission The efficiency of system software work and the service life of components. According to data analysis, about 70% of the common problems and difficulties caused by four column hydraulic pump stations in China, including foreign countries, are caused by pollution. When mechanical equipment causes common problems, you can immediately leave a message board, and everyone will assign you to deal with them. Of course, in normal maintenance, the customer must do such work well. The most important thing is oil pollution 1. The damage of oil pollution to the pump station is important in the following aspects:

1) The pollution of pump station components destroys all kinds of pollutants in the oil, leading to the destruction of components in various ways. Solid particles enter the clearance of the motion pair, causing milling damage or fatigue damage to the surface of parts. The damage of solid particles in high-speed fluid to the surface of components will cause corrosion damage. The water in the oil and the products of oil oxidation and mildew will cause corrosion to the components. In addition, the vapor in the oil of the pump station causes cavitation, which leads to corrosion and damage of the element surface.

2) Common problems of component blockage and clamping Solid particles block the clearance and branch pipe of the hydraulic solenoid valve, resulting in valve core blockage and clamping, damaging working performance, and even leading to more serious safety production accidents.

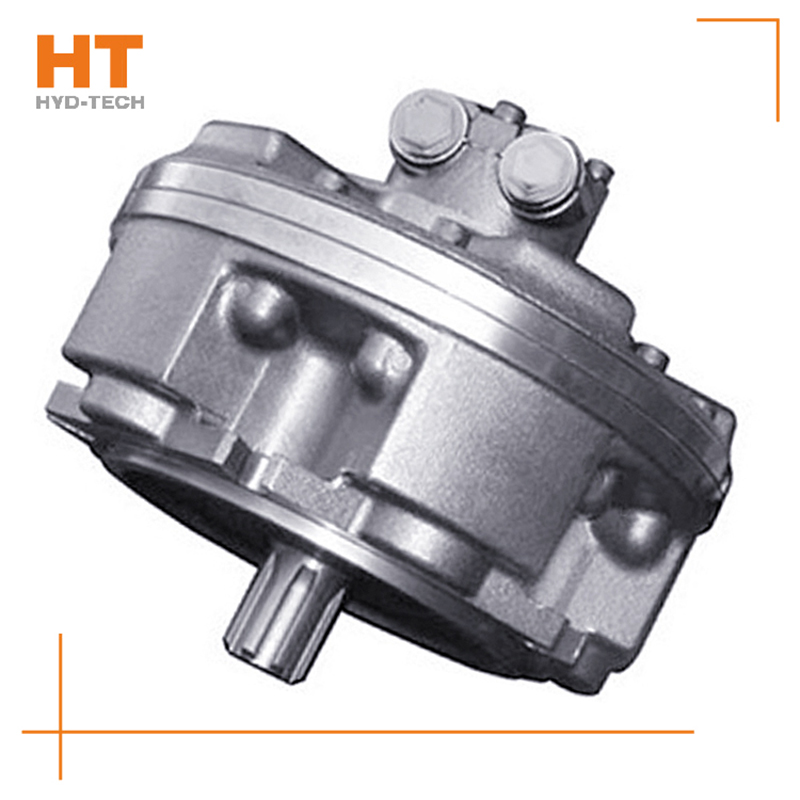

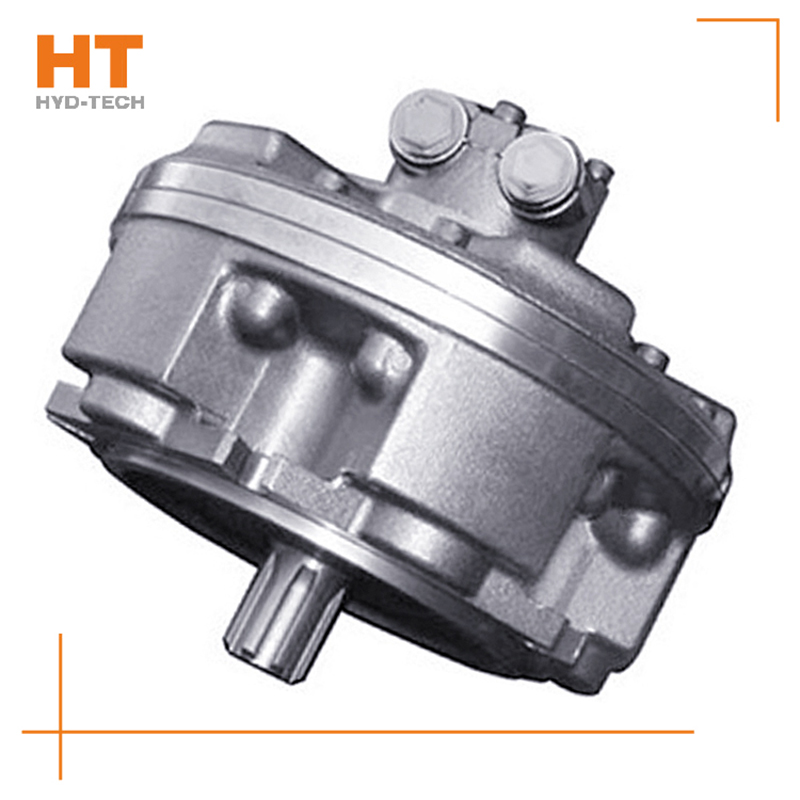

3) Raise the cycloid hydraulic motor Deterioration of oil performance The water and vapor in the oil is an important criterion for oil oxidation because of its electric energy, while the metal composite particles in the oil play an important role in catalyzing the oxidation of the oil. In addition, the water and suspended bubbles in the oil significantly reduce the tensile strength of the floating oil between the motion pairs, reducing the lubrication performance. Knowing the important pollution subordination of the pump station, we should always make sure to prevent problems before they happen, and the daily affairs management staff should take preventive measures against pollution. We can help you to deal with the pollution of the pump station immediately after we find it.

![]()