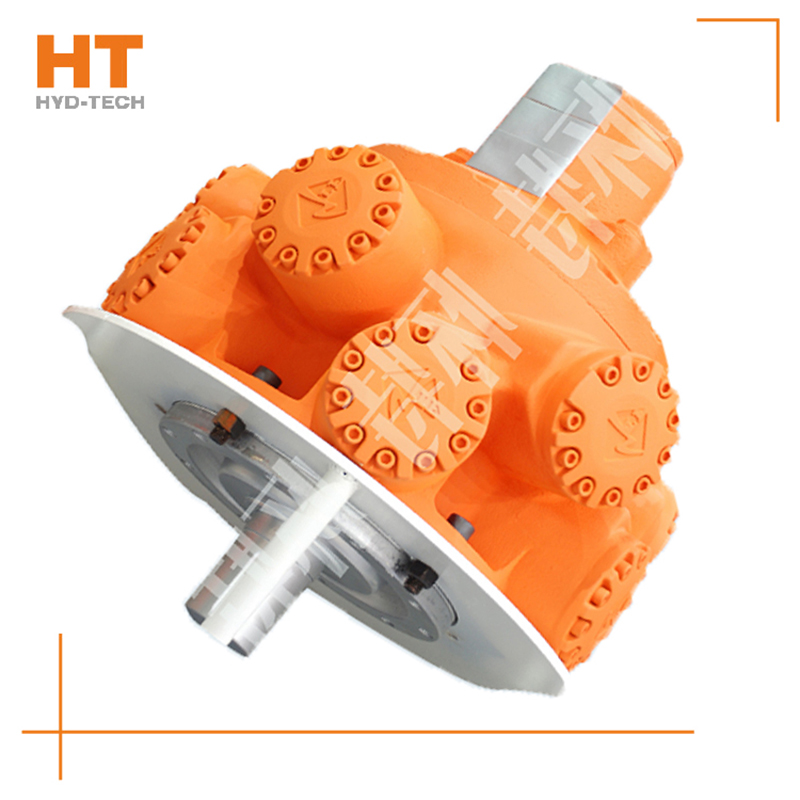

High installation with negative pressure balance Hydraulic motor In order to improve the current situation of low speed and large torque hydraulic motors in the sales market, a hydraulic motor with high efficiency (mechanical energy, high capacity efficiency), high pressure, high installation and further improved service life was invented. The basic principle of negative pressure balance was flexibly used in the motor to improve the working characteristics of the motor.

1、 In the case of our motor feeding liquid in cavity B, the pressure oil is fed by a plane of the oil distribution plate according to High speed gear hydraulic motor From the main oil passage to the other plane, because there is an annular oil groove, the pressure oil can work evenly on the plane of the oil distribution plate, so it can ensure that the parallel surface between the oil distribution plate and the surface works, and can reasonably reduce the sliding friction between the two surfaces during fitness exercises. The leakage amount of pressure oil is very small, and the capacity efficiency is further improved.

2、 In the case of our motor feeding fluid in cavity A, the pressure oil is fed from the round surface of the oil distribution plate. According to the main oil passage to the two planes, there is a safety channel to reach two planes of the motor immediately after the high pressure oil enters from the oil inlet hole. The oil in one plane immediately reaches the working cavity of the motor, and the oil in one plane flows to the oil inlet according to the gap with the oil passage plate, Therefore, the pressure oil can also have a symmetrical effect on the plane of the oil distribution plate, ensuring that the parallel surface between the oil distribution plate and the surface can reasonably reduce the sliding friction between the two surfaces during fitness exercises. The leakage of the pressure oil is very small, and the capacity efficiency is further improved.

3、 First of all, 20CrMnTi is selected as the material of plunger pump, which is suitable for making key parts that can bear heavy load, impact and friction.

Open a dialog box with a large total area on the mating surface between the plunger pump and the roller bearing surface, so that the high pressure oil can flow here and cause a driving force to the roller bearing surface, reducing the sliding friction of the two surfaces, thus achieving the balance of negative pressure, making the motor more stable and smooth during operation, and improving the mechanical energy.

Because the roller bearing is simple in structure, convenient in production and processing, and does not have stress points, it is more reliable. Therefore, the structure of roller bearing and plunger pump can bear a great load capacity and improve the working efficiency of the motor.

4、 During the operation of the hydraulic motor, the high-speed rotation and pressure will cause great deformation between the engine cylinder block and the housing, which will damage the motor. Therefore, we have selected a new secret aluminum alloy material for the motor, and immediately opened an oil groove in the hole matching with the engine cylinder block, so that the high pressure oil can flow into the housing oil groove, achieving the actual effect of negative pressure balance. It has got rid of the defect of oil-free bearings widely used in basic motors (oil-free bearings are very easy to deform under the condition of high speed ratio). On the one hand, it can improve the motor speed ratio, on the other hand, it can also improve the service life of the motor at a very large level.

![]()