Hydraulic motor of agricultural machinery yes Hydraulic transmission The system is not only an implementation component, but also an organization in the work of machinery and equipment. It changes the liquid pressure energy given by the hydraulic oil pump into the kinetic energy of rotating machinery, which is mainly used in injection molding machinery, ship accessories, engineering machinery, construction machinery, coal mine machinery, mining equipment, metallurgical equipment, petrochemical equipment, port machinery, etc.

As we all know, the motor has two oil inlet and outlet holes. If the pressure level of the oil inlet and outlet holes is higher, the torque of the output shaft transmission system will be greater. There is a positive correlation between pressure and torque. The commonly said "very strong" motor basically means the greater the pressure it bears. However, limited by many factors such as design scheme organization, raw material performance, heat treatment process, production and manufacturing precision, installation clearance, pressure resistance of hydraulic seals, cleanliness and so on, there are individual differences in the higher pressure resistance value of various types of motors and even each motor, which usually determines the industry application scope of various types of motors and the service life of each motor.

High voltage motor refers to the only way of development trend. I will briefly talk about the convenience and economic benefits of high voltage motor application to customers. For example, if there are two motors a and b of the same type in two enterprises, and their great pressure is 10 meters pa and 50 meters pa, then it is likely that if the customer completes the output of the same force, the exhaust volume of motor a will need to double or the total number will double. So far, the volume, net weight and cost of customers' entire machinery and equipment will increase, And the matching hydraulic pump and even all hydraulic transmission systems will also be expanded. to make a long story short, High pressure hydraulic motor It can make the machine and equipment of automobile manufacturers more compact, better performance, higher efficiency, lower cost and higher application safety. At this stage, the sales market is more and more eager to give feedback on the improvement of the motor pressure level. Due to the fierce market competition in the sales market, this factor may also determine the survival of hydraulic press manufacturers.

The modernization trend in China has a rapid rhythm and attaches importance to the stability and low cost of goods. Therefore, motors must continue to move towards high pressure, or they will be eliminated, which is just a problem of time. So, how can the motor increase the pressure? I think the key is to rely on solid basic skills and non-stop independent innovation and certification. One of the 100 motors has low pressure, and the impression of customers on the pressure of the motor is likely to stay here, because it is inconvenient for customers. Only solid basic skills can make the goods better and better, followed by keeping pace with the times, Due to the difference of design scheme structure, raw material type, heat treatment process, sealing structure and other elements, they immediately decide the difference of motor pressure level, so they should always take a higher overall goal to constantly try independent innovation and certification, and diligently promote Hydraulic motor High pressure.

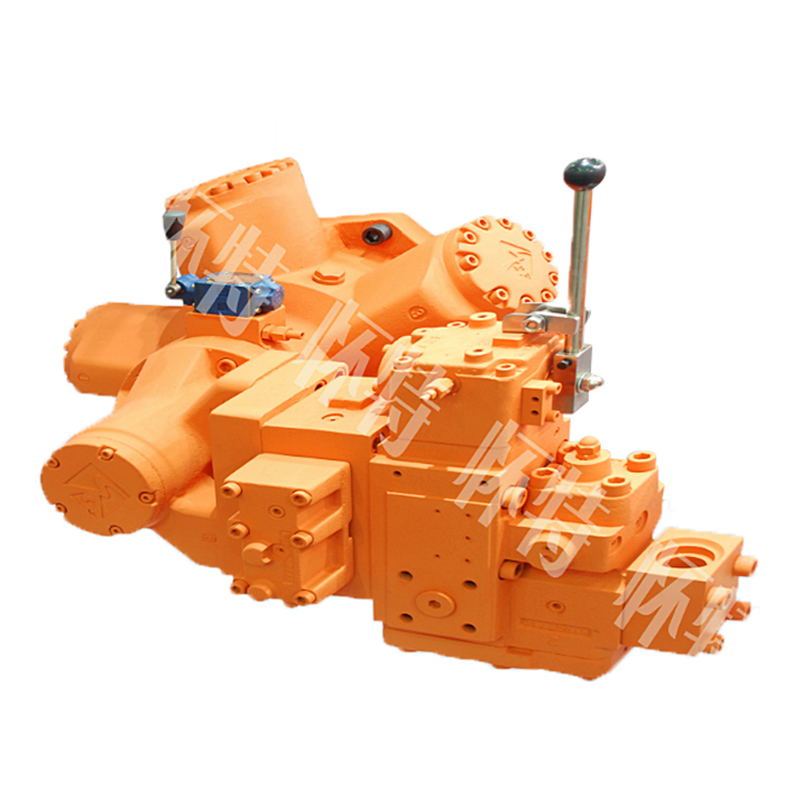

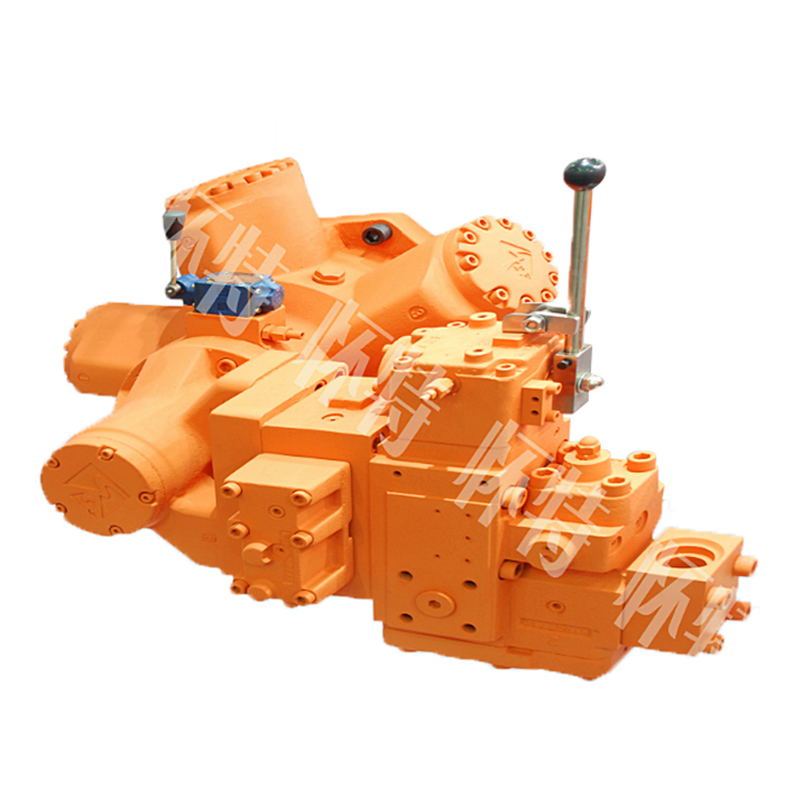

![]()