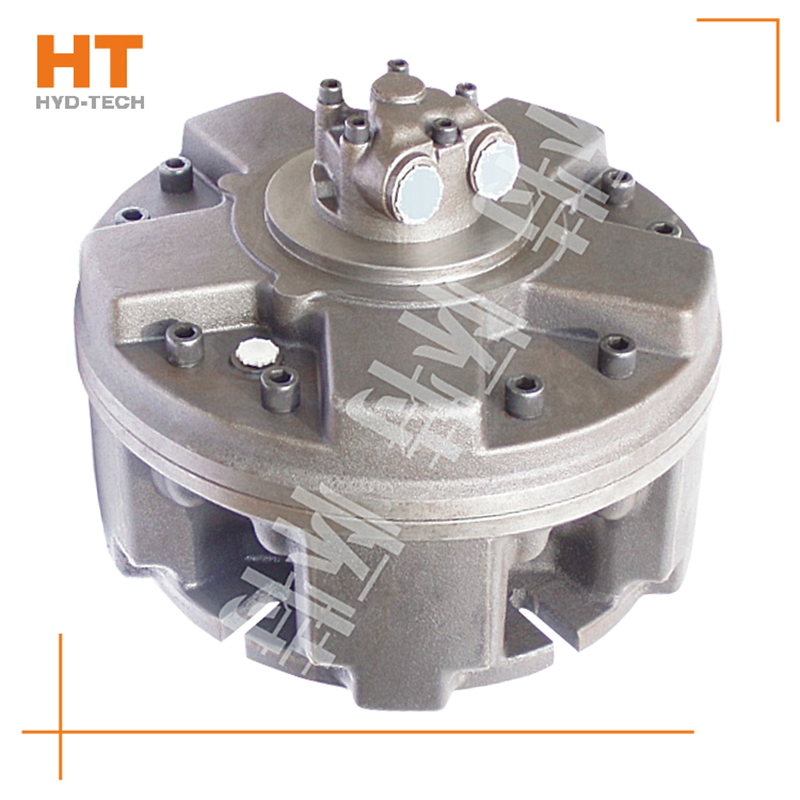

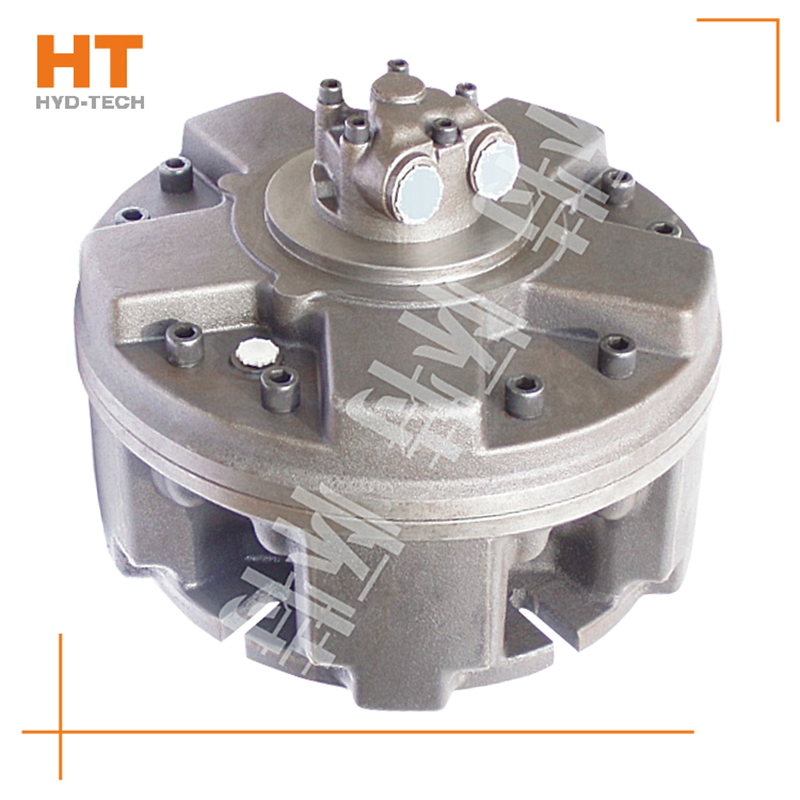

Hydraulic motor of agricultural machinery Because of its high efficiency, reliability, compact structure and other characteristics, it is used in the driving force rotation system software of mechanical equipment such as drilling machines.

1. Agricultural machinery Hydraulic motor Structure and basic principle of

The hydraulic motor of agricultural machinery is of inner hole flow distribution and working pressure compensation type. The key components are output shaft, machine cover, rolling bearing, long coupling shaft, rolling bearing housing, stator motor rotor pair

The valve disc, small coupling shaft, port plate and its moment spring yellow are composed (this type of hydraulic motor has the characteristics of low speed and large torque.

2. Reasons for the decrease of hydraulic motor performance

1. Wear condition of hydraulic motor

The hydraulic motor downloaded from the drill rig is found to be severely worn and deeply worn on the friction surface between the port plate and the valve plate after disassembly and inspection

0.15mm; The output shaft framework seal leaks oil.

2. Cause of oil leakage of output shaft framework seal

The disassembly inspection test shows that the axial and radial clearance of the output shaft meet the requirements, and the mating surface between the output shaft and the framework seal is not significantly worn. however

It was found that the vulcanized rubber for skeleton sealing became brittle and hard, and the ductility decreased. After the sealing lip of the framework is worn, the preload and oil sealing performance are reduced, and the temperature is too high

Speed up the wear of the sealing lip of the framework; In addition, because of the internal leakage of the hydraulic motor, the back pressure in the housing is too high, which makes the framework sealing lip grind

The damage and oil leakage are further aggravated.

3. Causes of valve plate wear

According to the principle of this hydraulic motor, the port plate and the motor rotor of agricultural machinery are connected by a small coupling shaft and rotate together

Make rolling rotation on the valve disc. The causes of excessive wear of the friction pair are as follows:

When a new hydraulic motor was just installed, the friction surface of the friction pair was insufficient because the motor housing was not filled with gear oil

Wear caused by lubrication. In particular, it carries heavy load in the early stage of the work, which makes the wear of the valve plate more serious. The friction between the valve plate and the valve plate

Because the surface roughness of the worn surface decreases, the storage space of the middle residue of the friction pair increases, and the fine particles entering the friction surface are

The metal material particles cut out rotate with the port plate, which aggravates the wear. Hydraulic transmission The filter element of the system is invalid, making the gear oil infiltrate

Granular residues and small fine particles enter the friction surface during the whole process of valve plate rotation, causing wear of wear-resistant materials on the friction surface. because

The wear between the port plate and the valve plate causes the gear oil to connect in the middle of the oil inlet and pump passages. Under the high pressure effect

The sealing, cleaning and heat removal performance of the pressure oil is reduced, the temperature is increased, and the wear is increased.

4. The reason of the hydraulic motor's fatigue

According to the root cause of port plate wear, the key reasons for the hydraulic motor fatigue are as follows:

Because the valve plate is worn, the inlet and pump oil passages are connected at the valve plate, part of the high pressure oil leaks, and the steam pressure flowing through the stator rotor pair decreases,

The total flow decreases, and finally the output speed ratio and torque of the motor decrease. Because the port plate is worn, its position relative to the valve body

The spring on the oil circuit board reduces the preload and adhesion between the port plate and the valve disc, which aggravates the leakage of gear oil,

As a result, the performance of the hydraulic motor is reduced.

The increase of gear oil temperature leads to the reduction of its comprehensive performance, which further reduces the working capacity of its driver agricultural machinery motor rotor rotation.

Through inspection, it is verified that there is no obvious wear on the rotor pair of the motor and the fusion surface of the rolling bearing shell and the valve disc which are matched with both sides. All fitness activities are normal without stagnation,

![]()