In industrial production, hydraulic valve is the most commonly used control system, which is mainly used for Manufacturer of cycloidal hydraulic motor The control of the oil flow direction in the hydraulic system can also effectively regulate the pressure and flow. There are three main types of hydraulic valves, namely pressure valve, direction valve and flow valve. For the same type of valve, the enterprise can select different functions according to different action mechanisms. Although there are various hydraulic valves, they always have basic common ground.

As far as the structure of hydraulic valves is concerned, all hydraulic valves include valve bodies, valve cores, and elements that drive the action of hydraulic valve cores. The elements here mainly refer to springs and electromagnets. In fact, the working principle of all hydraulic valves is the same. Their opening size, the pressure difference between the inlet and outlet of the valve body, and the flow through the valve must conform to a certain proportion. Moreover, various hydraulic valves can control their own different parameters according to actual needs.

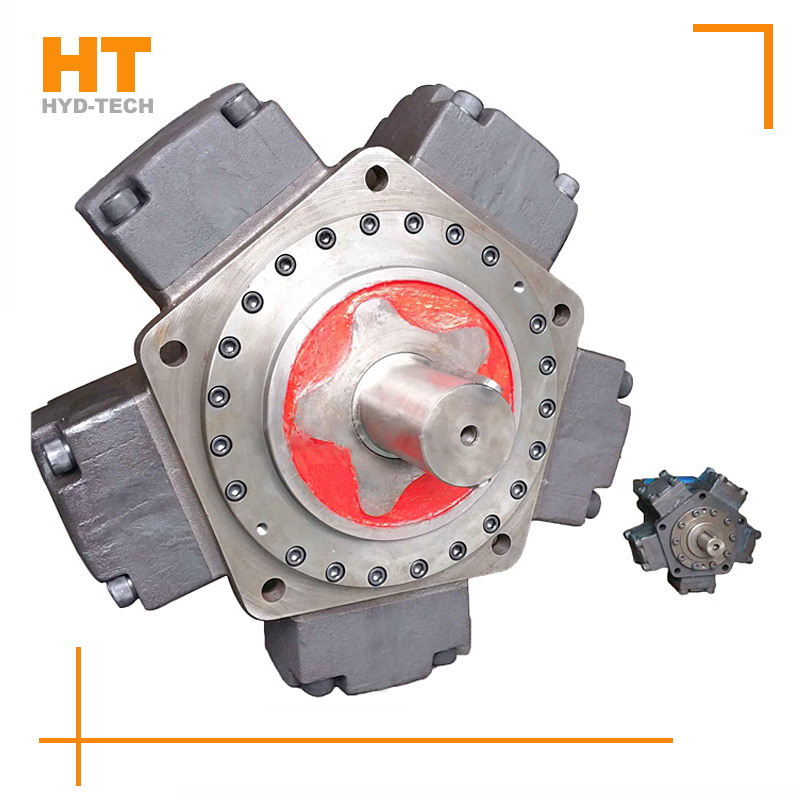

In actual work, what requirements should the hydraulic valve meet? Experts pointed out that the hydraulic valve must be sensitive and reliable, Five star hydraulic motor Small shock and vibration shall be ensured during operation. In addition, small oil overpressure, small loss and good sealing shall be ensured. Compact structure is the most basic requirement of hydraulic valve, and it is very convenient for maintenance, installation, adjustment and use, with strong versatility.

In order to ensure the normal operation of the hydraulic system, the enterprise must do a good job in hydraulic internal cleaning at ordinary times, so Travel hydraulic motor Before the new equipment is put into use, the hydraulic system must be free from pollution. but High torque hydraulic motor It is inevitable that the internal pollution of the hydraulic valve will be caused during use, so we need to pay attention to the cleaning of the internal components. If there are burrs, chips and other pollutants inside the new element, it indicates that the element is greatly affected during storage and transportation. At this time, the oil tank needs to be thoroughly cleaned. If necessary, measures should be taken to remove the pollutants to avoid safety failures caused by equipment operation.

![]()