Installation of one hydraulic cylinder:

During installation, ensure that the direction of the top joint of the piston rod is consistent with that of the cylinder head, earring, (or) hinge joint, and ensure the straightness of the entire piston rod during the advance and retreat process to prevent the occurrence of rigid interference and unnecessary damage.

Before commissioning, after the hydraulic cylinder is installed, oil should be added to the earrings, intermediate hinge shaft and other parts.

Commissioning of dual hydraulic cylinders.

Requirements for hydraulic oil.

1.1 Observe the pressure and temperature change amplitude.

1.2 The oil used by the system shall be consistent with the oil allowed by the oil cylinder for inspection.

1.3 Commonly used DIN51524 standard mineral oil.

Exhaust requirements of hydraulic cylinder.

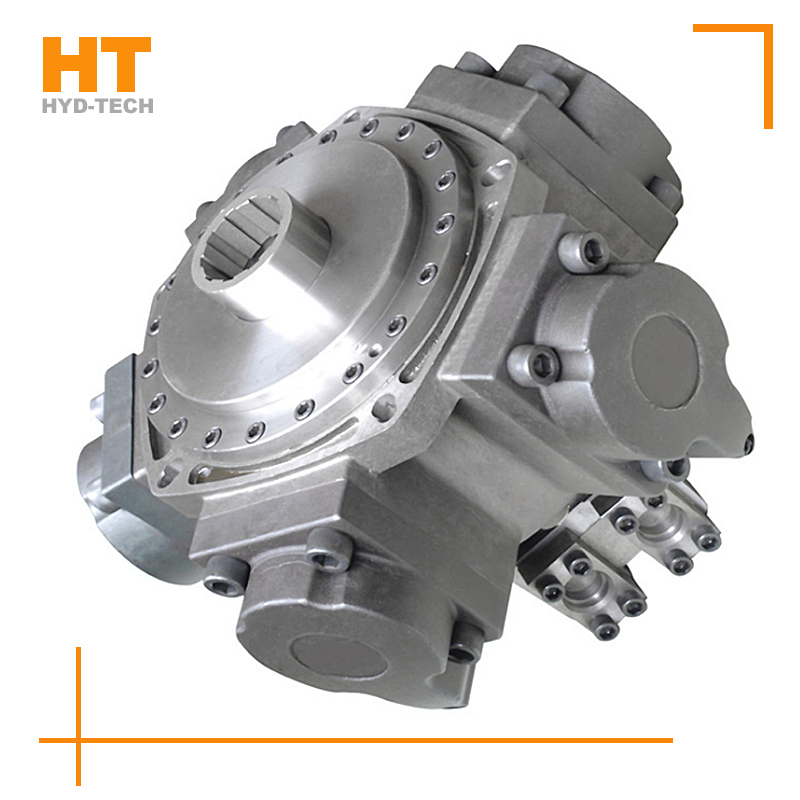

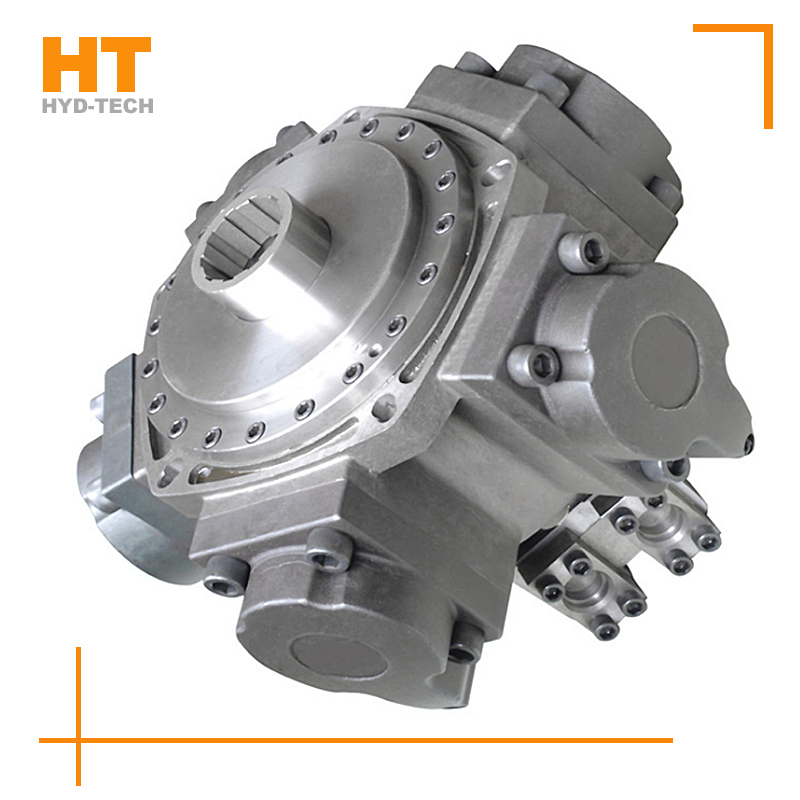

two point one Double output cycloidal motor Under no-load pressure, let the oil cylinder work repeatedly for a period of time, Cycloidal motor with shaft flow distribution Allow the air in the cylinder and pipe to drain.

2.2 Loosen the screw plug on the cylinder with exhaust screw plug, and lock the screw plug when it is checked that there is no bubble in the oil liquid.

Add exhaust device; If there is no exhaust device, the hydraulic system can be started, Plate port cycloidal motor The stroke of the working parts can be moved quickly to force the exhaust air.

Adjust the sealing ring to ensure that it is not tight or loose, and ensure that the piston rod can be pulled back and forth smoothly by hand without leakage (generally allowing slight oil leakage)

Correct the concentricity of both sides;

Straighten the piston rod.

Check the parallelism of hydraulic cylinder and guide rail and correct them.

Boring repair, piston reassembly.

Rust and hair removal for light ones, and chipping for heavy ones.

The screw rod should not be tightened too tightly, usually by hand, to keep the piston rod in a natural state.

![]()