Article 1 General:

The pump operators and maintenance workers must receive relevant training, pass the examination, obtain corresponding qualification certificates, and work with certificates.

(2) All operators must wear labor protection (including work clothes, hats, shoes, gloves, etc.) as required. Women workers' hair braids should be coiled into the hats. They are not allowed to wear scarves, high-heeled shoes, slippers or bare feet in the workplace.

When cleaning the work site, it is not allowed to flush electrical appliances, cables, lighting, signal lines and equipment transmission parts with water, nor to drench bearing pads with water to cool them.

The construction site shall always be kept clean and tidy, the ground shall be free from coal, water, dust and sundries, and the equipment shall be free from coal, water, oil, electricity and gas.

All pressure protection, temperature protection and other locking devices must be complete and intact, sensitive and reliable, and pressure rejection is strictly prohibited.

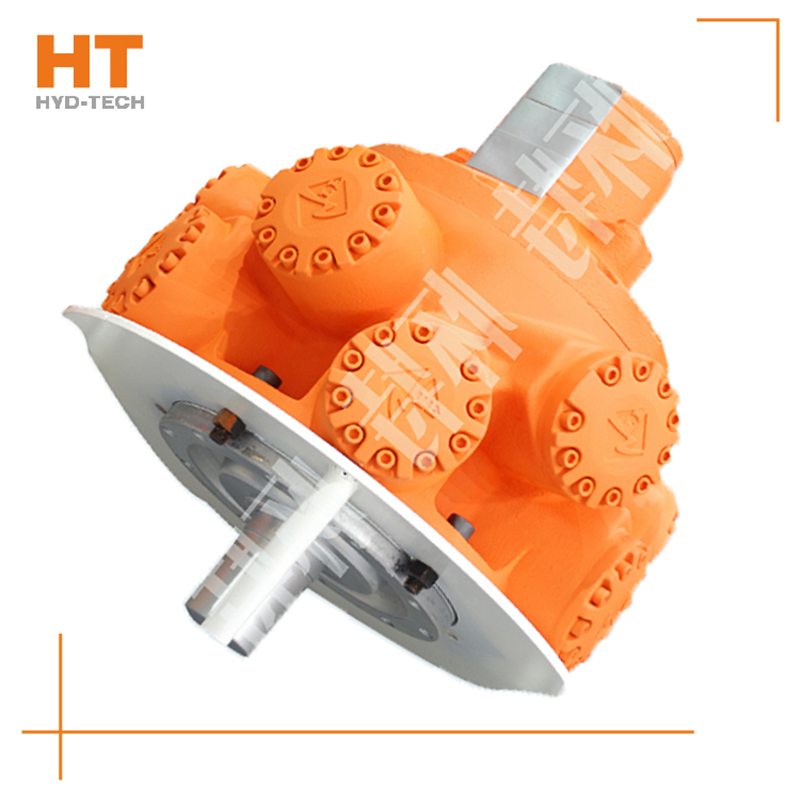

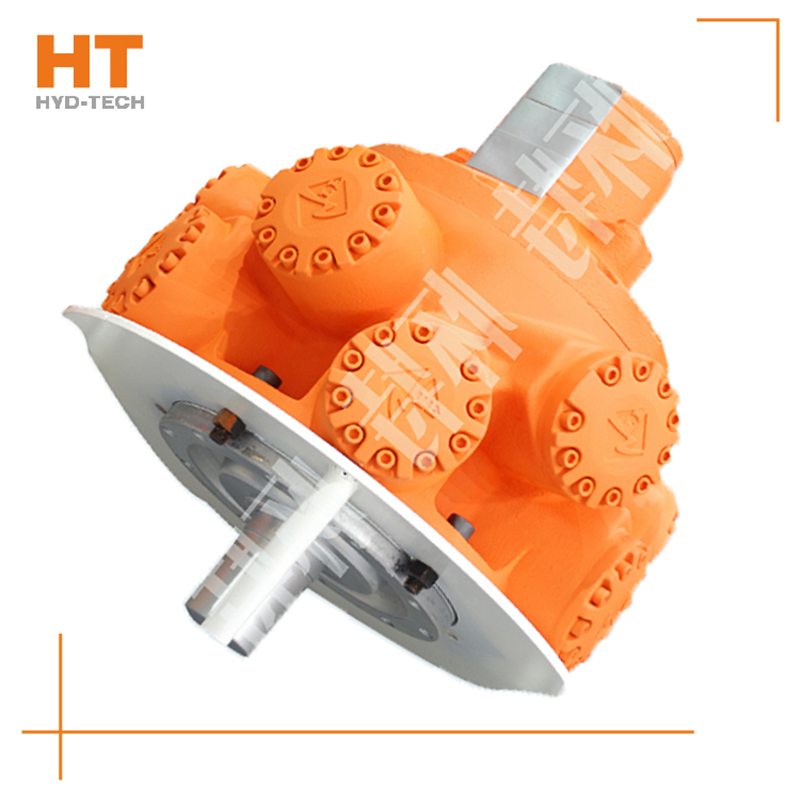

When the high-pressure flushing pump system fails during operation, it must stop working. Before repair, maintenance, cleaning and adjustment, OK Cycloidal hydraulic motor The "power off and tag out" system must be strictly implemented. All exposed rotating parts in the system must be installed with safe and reliable protective covers. When the protective cover is removed, it is not allowed to start. In special cases, detailed and strict supervision and prevention measures must be taken.

Movable protective railings shall be set around the system. It cannot be disassembled or moved during normal operation. Do not enter outside the operating range of the operator.

The system is a high pressure working equipment, and the management and operation requirements of corresponding vessels shall strictly comply with relevant regulations.

Second, operation steps.

I. Pre startup inspection:

Check whether all suction/discharge pipes are smooth, airtight and free from leakage. High speed hydraulic cycloidal motor Any on/off valve between the pump and the tank must be opened, and the filter has been correctly cleared to ensure that water can enter the pump body smoothly, and the pressure pipeline is in the vent state, so that the air in the pump can be discharged smoothly. In winter, the water tank, pipeline, and pump body must be prevented from icing. Check whether the oil level is normal.

Start the vehicle, stop the vehicle: start the vehicle.

First, the operation of plunger pump is divided into centralized automatic operation and local manual operation. In the normal production process, centralized automatic operation or centralized manual operation is adopted, OZ cycloidal hydraulic motor Only in case of overhaul or failure can on-site manual operation be adopted. The centralized and local conversion is controlled by the transfer switch on the control cabinet in the power distribution room. When set to the automatic position, it is centralized automatic operation, and when set to the manual position, it is local manual operation.

The second is the automatic operation mode of centralized control: after receiving the command to start the program in the centralized control room, after checking and confirming that there is no maintenance or other personnel working on the relevant equipment near the equipment and before and after it, notify the centralized control room to start the vehicle. In the process of startup, select the "flushing" program on the control screen, click the start button, and the program control will be completed automatically.

III

Field manual operation mode: first place the equipment in the field mode of the control cabinet. The start button of the equipment can be operated when it is confirmed through inspection that there is no maintenance or other personnel working on the relevant equipment near the equipment and at the front and rear.

3. Precautions during operation:

The pump must be started without load and operated for 3-5 minutes until the oil flow is stable before loading.

Check that the motor rotation speed does not exceed 1500r/min during operation.

3、 Check whether a small amount of water (several drops per minute) is discharged from the leakage outlet of the pool, and check whether the pump body has abnormal temperature rise, sound and vibration. In case of any situation, find out the cause, and then start the pump after treatment.

During the operation of high-pressure cleaning pump, no one is allowed to enter the warning area of high-pressure equipment. The oil level shall be checked at any time, and the oil shall be filled up in time in case of insufficient oil.

The special lubricating grease shall be regularly injected into the oil hole every 100 working hours, and the lubricating oil shall be replaced every 5000 working hours. The oil change period shall not exceed one year. When changing the oil, the pump shall be at the operating temperature.

![]()