Water cutting ultrahigh pressure water cutter, also known as water cutter and water jet, is a high-energy fluid (380MPa) produced by multi-stage pressurization of ordinary water, and then passed through a very thin ruby nozzle( Φ 0.1-0.35mm) at a speed of nearly kilometers per second, which is called ultrahigh pressure water cutting.

CNC water cutter consists of five parts: ultra-high pressure generator, CNC machine tool, full-automatic abrasive conveying system, and overall cutting head.

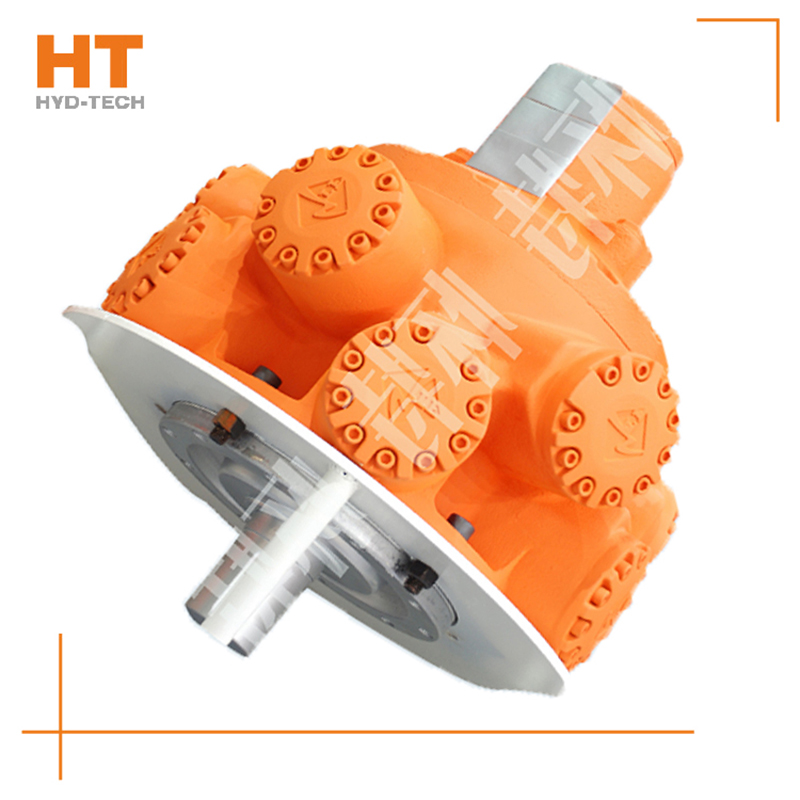

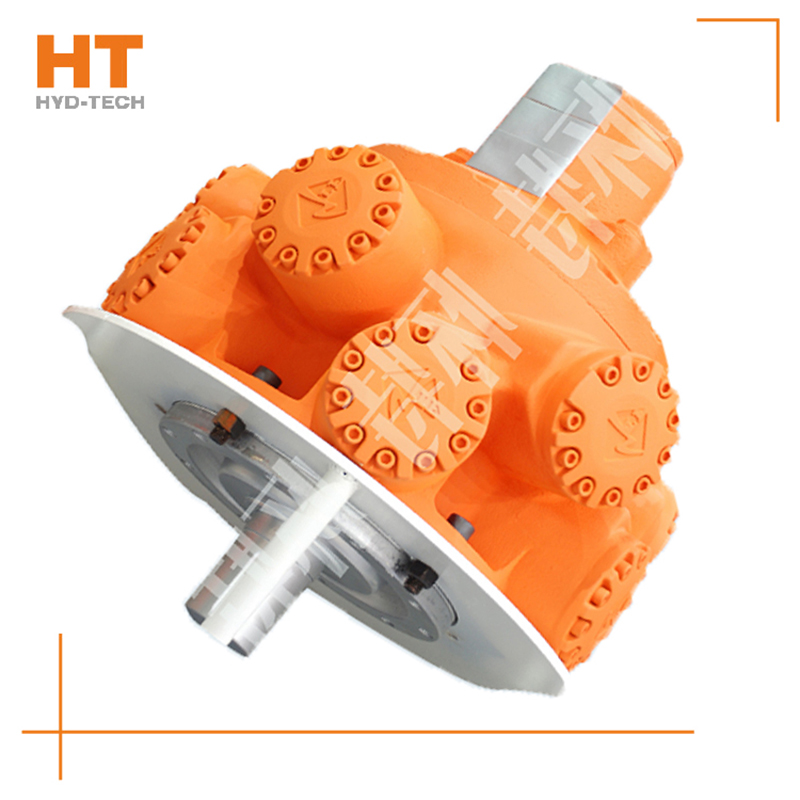

Water jet cutting machine is a multi-purpose cutting equipment with excellent performance. It is characterized by cutting non heat source with high-energy jet beam. There is no thermal process in the cutting process, so it can cut all metal and non-metallic materials, especially those difficult to cut with various hot cutting methods. Product features: fast cutting speed, BMSY cycloidal hydraulic motor The cutting shall be smooth, free of dust, thermal deformation and pollution, so as to reduce material waste. Materials that can be cut: titanium alloy, copper plate, steel plate, aluminum plate, cast iron, granite, marble, ceramic tile, chemical fiber, wood, cloth, paper, leather, plastic, etc. It is suitable for aviation, military, stone, architecture, decoration and other finishing enterprises.

There are three main uses of the water cutter. One is to cut non flammable materials, such as marble, tile, glass, cement products, etc., which cannot be processed by hot cutting; The second is to cut flammable materials, such as steel plate, plastic, cloth, polyurethane, wood, leather, rubber, etc. In the past, hot cutting can also be carried out, but it is easy to produce burning areas and burrs, while water cutting will not produce burning areas and burrs, and the physical BMK6 cycloidal hydraulic motor The mechanical properties remain unchanged, which is also a major advantage of water cutting; Third, cutting flammable materials, which cannot be replaced in other processing methods.

Compared with other cutting methods, water cutting has incomparable advantages. Water cutting is cutting. When you feel that the thickness of laser and plasma cutting is too thin, BMK2 cycloidal hydraulic motor If the burr is too big, which is bad for the heat affected zone, you can consider water cutting; When you feel that the burr of flame cutting is too large, the roughness is too poor, and the heat affected zone is too large, you can consider choosing water cutting; When you feel that the speed of wire cutting is too slow and you cannot cut non-conductive materials, you can consider choosing water cutting; When you feel that both circular saw and band saw can cut small holes, you can choose water cutting; When you feel that small holes are cut with a circular saw and a band saw, you can also choose water cutting; When you cut flammable and explosive materials or in flammable and explosive environments, you must consider choosing water cutting; When you cut, you should consider water cutting;

![]()