Water jet cutting equipment has its unique cutting advantages, so water jet technology is considered to be the most common and fastest developing technology in the world. Compared with other cutting technologies, the water jet cutter does not produce toxic and harmful gases or liquids, nor toxic and harmful substances or vapors. After water jet machining, there will be no thermal reaction zone or residual mechanical stress on the workpiece surface. Water jet cutter is indeed a multi-purpose, high-yield cold cutting technology. In order to reduce production costs, engineering and manufacturing departments have been looking for better cutting methods. Water jet scalpel technology has many unique functions and advantages, which can effectively reduce costs.

Water jet cutter is divided into non sand jet cutter and sand jet cutter.

No sand water knife.

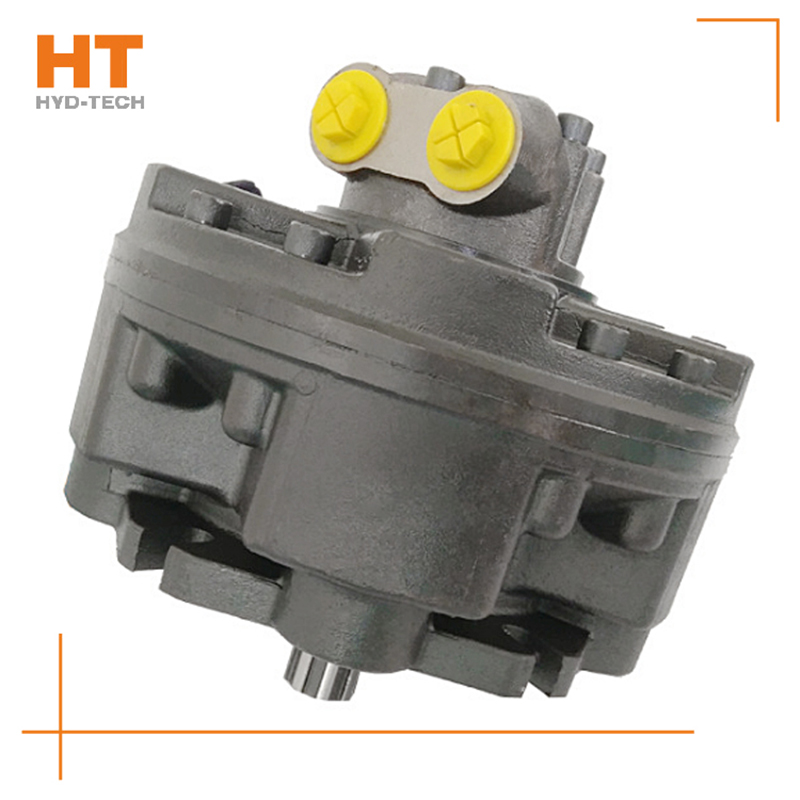

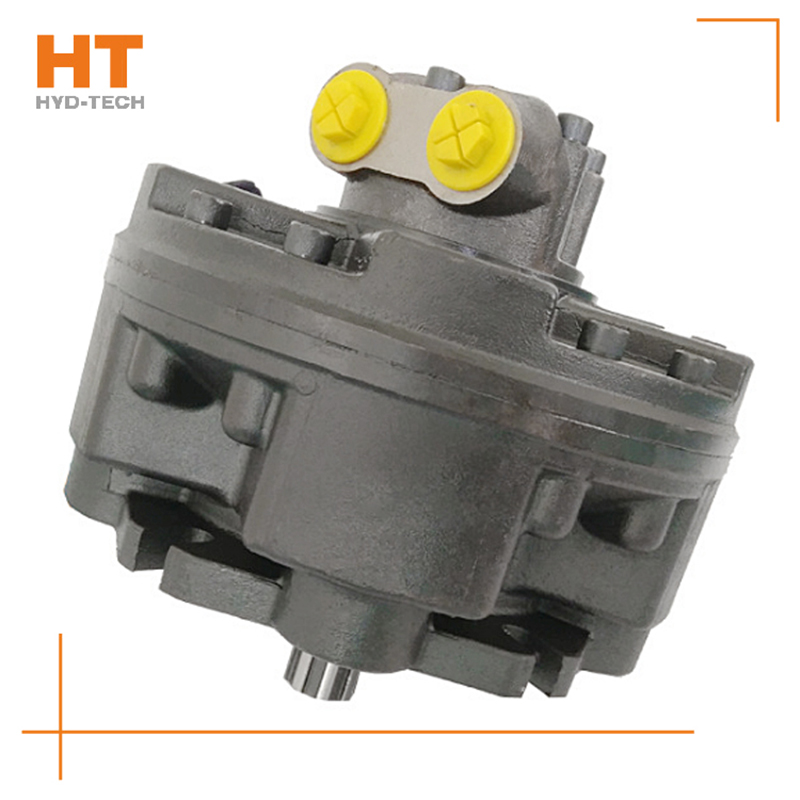

Sand free water jet cutter is a kind of direct water cutting method. Sand free water jet cutter has been commercially used to cut corrugated cardboard. Bm4 cycloidal hydraulic motor A large number of users use sandless water knives to cut diapers, paper towels and car interiors. When cutting tissue paper or diapers, the water vapor generated by sandless water knife operation is far less than that generated by contact or breathing. The unexpected shutdown caused by the common non water jet cutting process has caused a lot of economic losses to the manufacturers of diapers or tissue. The water jet equipment can provide all-weather, year-round safe use for the above industrial applications.

Sand filling water knife.

Sand free water jet cutter can only be used to cut some soft foundation materials, but for hard foundation materials such as steel, iron, stone, etc. The water knife without sand cannot cut or cut very slowly. If Plate port cycloidal hydraulic motor Adding a proper amount of abrasive into the water arrow can be used to cut almost all soft and hard materials.

There are some differences between sanding water jet and non sanding water jet. Sand free water knife etches materials through water jet, sand blasting accelerates sand blasting, and etches materials through accelerated sand blasting. The energy of sanding water jet is thousands of times that of non sanding water jet. of course Cycloidal hydraulic motor with brake Both non sand water jet cutter and sand water jet cutter have their own application fields. The non sand water cutter can cut soft materials, and the sand water cutter can cut hard materials.

Water cutting is a multifunctional cutting equipment with perfect performance. It is characterized by no heat source, high-energy jet machining, and no hot machining during cutting. Therefore, it can cut all metal and non-metallic materials, especially those materials that cannot be processed by various hot cutting methods. The utility model has the advantages of small and flat incision, no dust, no thermal deformation, no pollution and no waste of materials.

![]()