(1) Electro hydraulic proportional servo technology will continue to be popularized and applied. The hydraulic servo system will change from the previous electro-hydraulic on-oE system and open loop proportional control system to the closed-loop proportional servo system. In order to adapt to this development, the pressure, flow, position, temperature, speed, acceleration and other sensors must be standardized. Computer interfaces should also be unified and compatible.

(2) The flow, pressure, temperature, oil stain and other values of the hydraulic system will be automatically measured and diagnosed. As the price of the computer is reduced, the monitoring system, including the central monitoring and automatic regulation system, will be developed. The standardization of computer simulation, especially the requirements for high-precision, "advanced" systems. Widespread application of electronic direct control components, such as electronic direct control hydraulic pumps, High torque cycloidal hydraulic motor The application of universal control mechanism, as well as the status and development of electromechanical integration of hydraulic products, are also issues that need to be discussed in the future. Hydraulic industry:

——Hydraulic components are developing towards high performance, high quality, high reliability and system assembly; Develop towards energy saving, noise, vibration, leak free and environmental protection requirements; Develop towards environmental protection requirements such as the use of water-based media; Develop high integration, high power density, intelligence, electromechanical integration and light, small and micro hydraulic components; Actively adopt new processes, new materials, electronics, sensors and other high-tech.

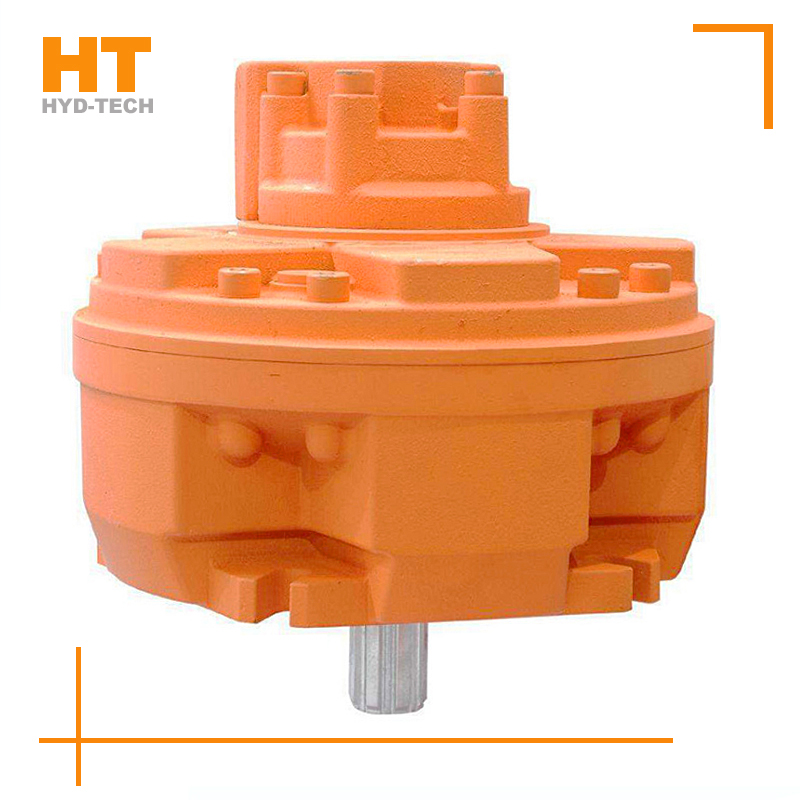

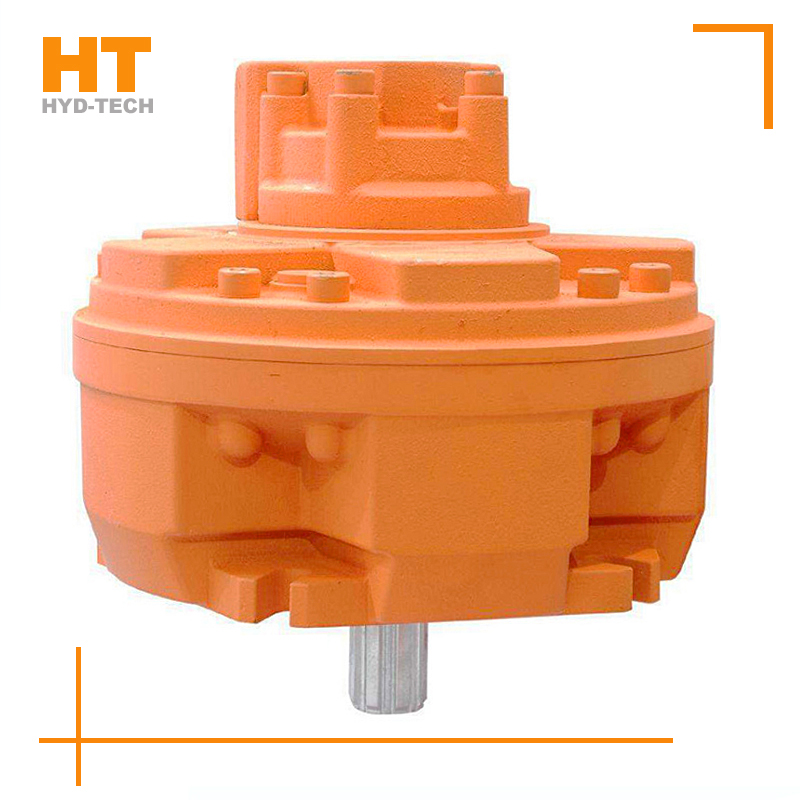

--The hydraulic coupling is developing towards high-speed, high-power, integrated hydraulic transmission, water medium speed regulating hydraulic coupling, automobile application, and hydraulic reducer, BMT hydraulic cycloid motor Improve product reliability and reduce mean time between failures; The development of hydraulic torque converter to high-power products, the improvement of parts manufacturing process, the improvement of reliability, the promotion of computer-aided technology, Positive and reverse cycloidal hydraulic motor Develop hydraulic torque converter matched with power shift transmission; The hydro viscous speed governing clutch is developing towards high power and high speed, improving product quality and forming batch;

![]()